Bearing Selection Guide

Bearing Selection Guide

Blog Article

Bearing Selection Guide

When it comes to machinery and equipment that involves moving parts, selecting the right bearings is crucial for optimal performance and longevity. Bearings are mechanical components that reduce friction between moving parts and support radial and axial loads. Choosing the appropriate bearings involves considering factors such as load capacity, speed, temperature, and environmental conditions. To navigate the complexities of bearing selection, it's essential to have a comprehensive bearing selection guide at your disposal.

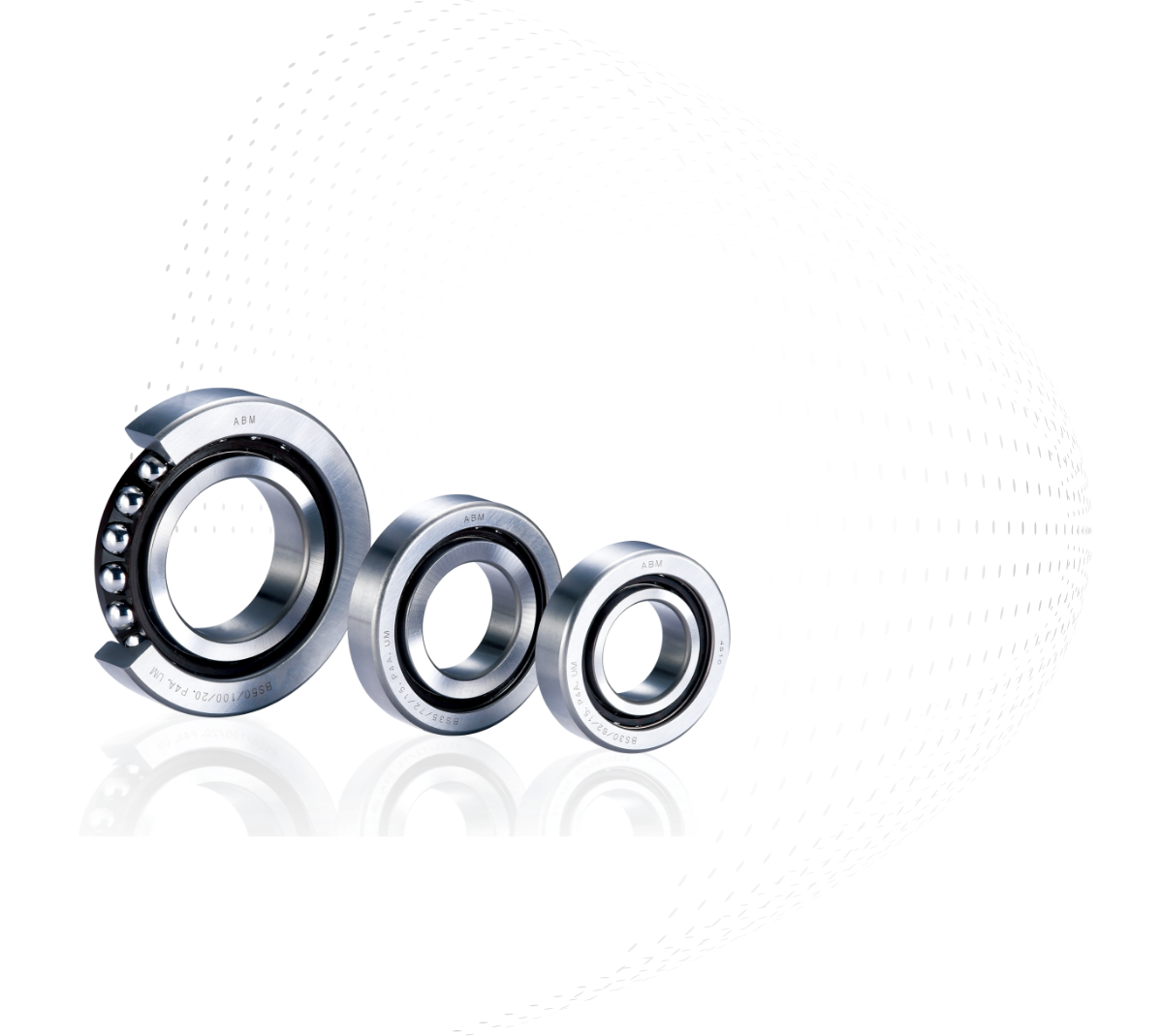

Understanding the Benefits of Ball Bearings

Ball bearings are one of the most common types of bearings used in various applications due to their versatility and efficiency. These bearings consist of balls sandwiched between two rings, allowing for smooth rotational motion while minimizing friction. The benefits of ball bearings include:

- Low friction

- High precision

- Quiet operation

- Long lifespan

However, it's important to note that ball bearings may not be suitable for heavy radial loads or high-speed applications. In such cases, alternatives like tapered roller bearings or spherical roller bearings may be more appropriate.

Do You Need to Purchase Bearings?

Whether you are an individual hobbyist or a large industrial operation, the need for bearings can arise in various scenarios. Here are some reasons why you might need to purchase bearings:

- Repairing machinery or equipment

- Upgrading to improve performance

- Building new prototypes or projects

- Stocking up for future maintenance needs

With a wide range of bearing types available in the market, it's essential to understand your requirements and select the right bearings for your specific application.

Factors to Consider in Bearing Selection

Choosing the correct bearings involves evaluating several factors to ensure optimal performance and longevity. Some of the key considerations include:

Load Capacity

One of the critical factors to consider in bearing selection is load capacity. The load capacity refers to the maximum load that a bearing can withstand before it fails. It is essential to understand the types and magnitudes of loads that the bearing will be subjected to, whether it's radial loads, axial loads, or a combination of both. Selecting bearings with the appropriate load capacity is crucial to prevent premature failure and ensure reliable operation over time.

Speed and Temperature

Another crucial aspect to consider is the operating speed and temperature of the application. High-speed applications require bearings capable of handling rotational forces without compromising performance or durability. Similarly, extreme temperatures can affect the material properties and lubrication of bearings, necessitating special considerations to maintain optimal functionality. By selecting bearings that are designed to operate efficiently at the specified speed and temperature ranges, you can enhance the overall performance and reliability of the machinery.

Environmental Conditions

Environmental conditions play a significant role in determining the lifespan and performance of bearings. Factors such as moisture, dust, chemicals, and other contaminants can impact the operation of bearings if not adequately addressed. Choosing bearings with appropriate sealing mechanisms and protection against environmental elements can help prevent premature wear, corrosion, and failure. By considering the environmental conditions in which the bearings will operate, you can ensure their longevity and reliability in challenging settings.

Load Capacity

Load capacity is a critical factor to consider when selecting bearings for various applications. The load capacity of a bearing determines its ability to support different types of loads, including radial and axial loads. Understanding the specific load requirements of your application is essential to choose bearings that can withstand the expected forces and prevent premature wear or failure.

For example, in heavy machinery applications where significant radial loads are present, selecting bearings with a high radial load capacity is crucial to ensure stability and longevity. Similarly, in applications with both radial and axial loads, choosing bearings that can handle combined loads effectively is essential for optimal performance.

By accurately assessing the load capacity requirements of your machinery or equipment, you can select bearings that meet or exceed these demands, thereby enhancing the reliability and efficiency of the system.

Conclusion

Whether you are a mechanical engineer designing complex machinery or a DIY enthusiast working on a personal project, understanding the nuances of bearing selection is essential for achieving optimal functionality and durability. By leveraging resources like a comprehensive bearing selection guide and exploring the benefits of different types of bearings, you can make informed decisions that align with your specific needs and requirements.

Remember, when it comes to purchasing bearings, knowing the types of bearings available and their suitability for your application is key to ensuring smooth operations and avoiding costly downtime due to premature failures.

Report this page